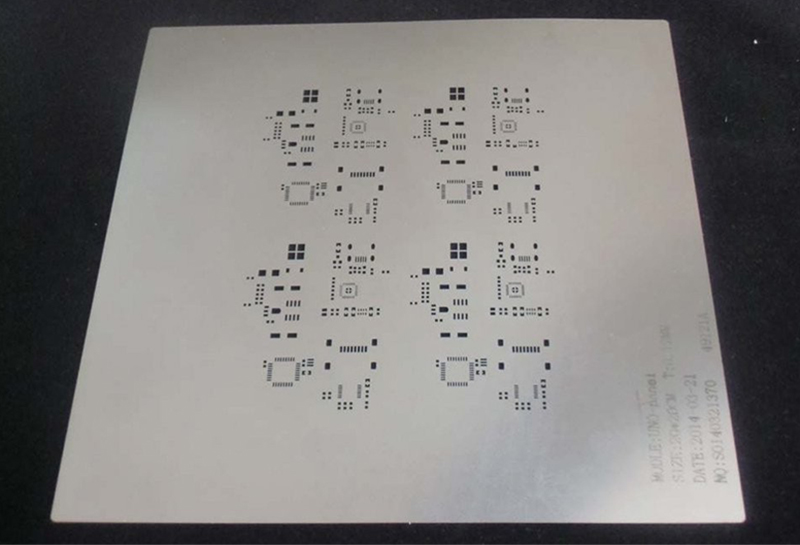

Stainless Stencil

Shop stainless stencils to create professional designs. Our factory produces high-quality stencils for a variety of applications. Order now!

Request a QuotePRODUCTS DETAILS

Hot Products

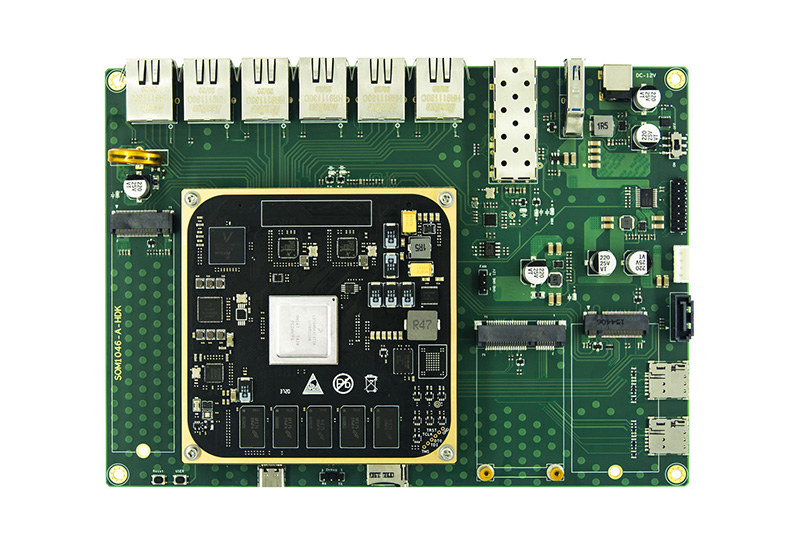

Artificial intelligence 8 layer pcb with vais in pad tech

PCBA Laser-cut stencil manufacturing service

6 layer flexible pcb

6 layer ENIG pcb

Ultrasound board gerd treatment board

Aluminum metal core pcb

Digital Camera main board for CCTV

Microwave Power amplifier PCB Assembly in China

Rogers RT5880 high frequency/ high speed pcb of filled vias

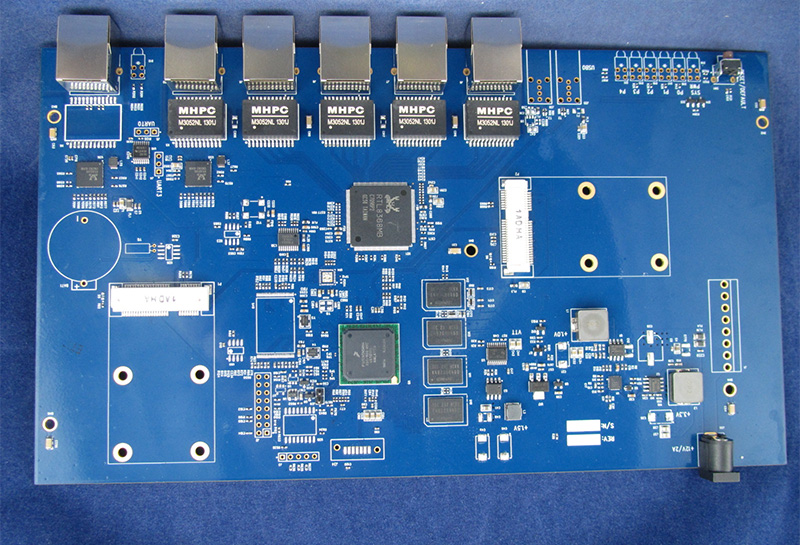

Industrial Main board PCBA projects manufacturing

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours