Top SMD PCB Assembly Services: Expert PCB Assembly Solutions Available Now

By:Admin

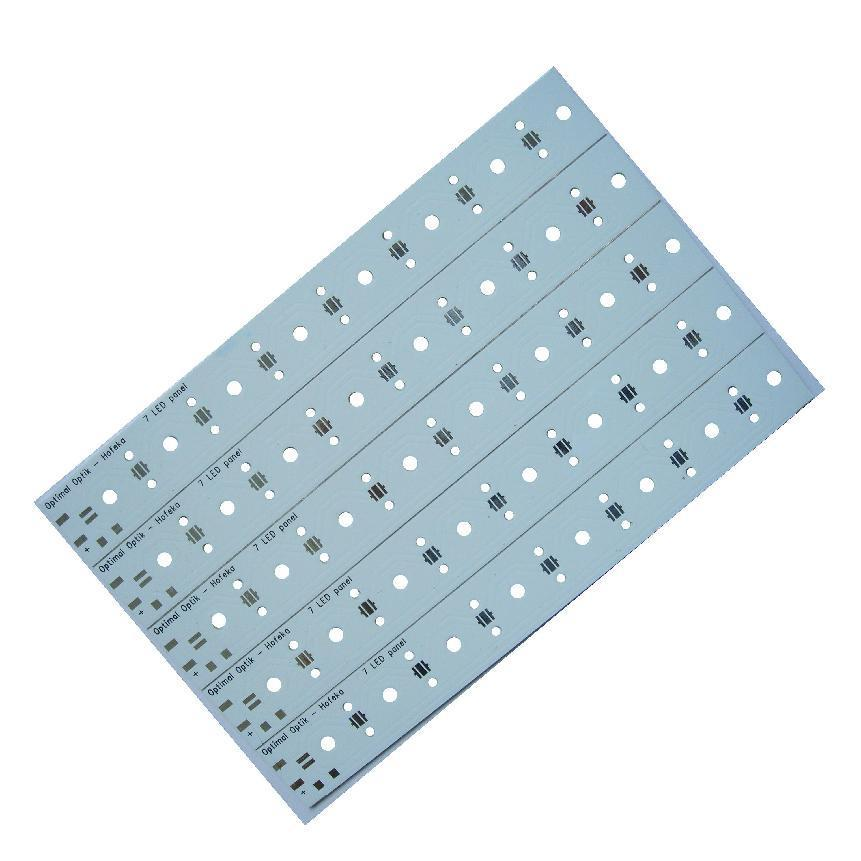

In today's fast-paced and technologically driven world, electronics play a crucial role in almost every aspect of our lives. From the smartphone in our pockets to the smart appliances in our homes, electronics have become an integral part of our daily routines. As the demand for smaller, faster, and more efficient electronic devices continues to rise, the need for advanced manufacturing techniques becomes increasingly important. This is where SMD PCB assembly comes into play.

{} is a leading provider of SMD PCB assembly services, specializing in the production of high-quality, advanced technology PCBs for a wide range of industries. With a state-of-the-art manufacturing facility and a team of skilled engineers and technicians, {} is at the forefront of the electronics manufacturing industry. Their innovative approach to SMD PCB assembly has earned them a reputation for excellence and reliability, making them a trusted partner for companies looking to bring their electronic products to market.

SMD, or Surface Mount Device, PCB assembly is a manufacturing process that involves attaching electronic components directly to the surface of a printed circuit board (PCB). This is in contrast to the older through-hole technology, which required the leads of components to be inserted into holes in the PCB and then soldered in place. SMD assembly offers several advantages over through-hole assembly, including a smaller footprint, higher component density, and improved electrical performance.

One of the key benefits of SMD PCB assembly is its ability to support the production of smaller, lighter, and more efficient electronic devices. By eliminating the need for bulky through-hole components and creating a more compact PCB design, SMD assembly allows manufacturers to pack more functionality into a smaller space. This is essential for products like smartphones, tablets, and wearable devices, where size and weight are critical design considerations.

In addition to its space-saving advantages, SMD PCB assembly also offers improved electrical performance. The shorter connection distances and reduced parasitic effects of SMD components lead to lower signal losses, better high-frequency performance, and overall improved reliability. This is crucial for electronic devices that rely on high-speed data processing and wireless communication, as even small improvements in performance can have a significant impact on the end user experience.

With the growing demand for smaller, faster, and more efficient electronic devices, SMD PCB assembly has become an essential manufacturing technique for companies across a wide range of industries. From consumer electronics to automotive, aerospace, and medical devices, SMD assembly is driving innovation and enabling the development of the next generation of electronic products.

{} is proud to be at the forefront of this technological revolution, offering a comprehensive range of SMD PCB assembly services to support their customers' manufacturing needs. From prototype development to full-scale production, {} leverages their expertise and state-of-the-art manufacturing facility to deliver high-quality, reliable PCBs that meet the exacting standards of their clients.

As the demand for smaller, faster, and more efficient electronic devices continues to grow, the importance of advanced manufacturing techniques like SMD PCB assembly will only increase. With their innovative approach and commitment to excellence, {} is well positioned to lead the way in the future of electronics manufacturing.

In conclusion, SMD PCB assembly is a crucial manufacturing technique that is driving innovation and enabling the development of smaller, faster, and more efficient electronic devices. With their expertise and state-of-the-art manufacturing facility, {} is a trusted partner for companies looking to bring their electronic products to market. As the demand for advanced electronics continues to grow, {} is well positioned to lead the way in the future of electronics manufacturing.

Company News & Blog

Ultimate Guide to SMD Circuit Design and Manufacturing

SMD Circuit Introduces Cutting-Edge Technology for Electronic DevicesSMD Circuit, a leading manufacturer of electronic components and circuits, has recently introduced a revolutionary new technology that is set to transform the way electronic devices are designed and manufactured. This new technology, which is the result of years of research and development, promises to make electronic devices smaller, more efficient, and more powerful than ever before.The new technology, known as Surface Mount Device (SMD) technology, is a type of electronic circuit in which the components are mounted directly onto the surface of the printed circuit board (PCB), as opposed to being inserted into holes on the board. This allows for a much denser and more compact design, as well as a significant reduction in the size and weight of the final product. In addition, SMD technology also offers improved thermal performance and higher levels of reliability, making it ideal for a wide range of applications.SMD Circuit has long been at the forefront of innovation in the electronics industry, and this latest development is a testament to their ongoing commitment to pushing the boundaries of what is possible in electronic design and manufacturing. With the introduction of SMD technology, the company is poised to revolutionize the way electronic devices are made, paving the way for smaller, more advanced, and more versatile products in the future.In addition to the introduction of SMD technology, SMD Circuit is also known for its extensive range of electronic components, including resistors, capacitors, diodes, and integrated circuits. These components are used in a wide variety of electronic devices, from smartphones and tablets to medical devices and industrial equipment. With a proven track record of quality and reliability, SMD Circuit has earned a reputation as a trusted supplier of electronic components to some of the world's leading electronics manufacturers.Furthermore, SMD Circuit's commitment to sustainability and environmental responsibility sets them apart from other companies in the industry. The company adheres to strict environmental standards in its manufacturing processes, and is dedicated to minimizing its impact on the environment. This commitment to sustainability extends to the design of their products as well, with an emphasis on energy efficiency and recyclability.With the introduction of SMD technology, SMD Circuit is poised to build on its reputation as an industry leader in electronic design and manufacturing. The company's innovative approach to technology and commitment to sustainability make it an attractive partner for electronics manufacturers looking to stay ahead of the curve."We are excited to introduce our new SMD technology to the market," said a spokesperson for SMD Circuit. "We believe that this new technology has the potential to revolutionize the way electronic devices are designed and manufactured, and we are confident that it will be well-received by the industry. We are committed to pushing the boundaries of what is possible in electronic design and manufacturing, and we look forward to seeing the impact that SMD technology will have on the electronics industry."As the demand for smaller, more efficient electronic devices continues to grow, SMD Circuit's innovative new technology is well-positioned to meet the needs of the market. With a proven track record of quality, reliability, and sustainability, SMD Circuit is poised to lead the way in the development of cutting-edge electronic components and circuits for years to come.In conclusion, SMD Circuit's introduction of SMD technology represents a significant milestone in the company's history, and a major step forward for the electronics industry as a whole. With its innovative approach to technology and unwavering commitment to sustainability, SMD Circuit is well-positioned to drive the future of electronic design and manufacturing.

Top Tips for Choosing the Best Circuit Card Assembly in 2022

Circuit Card Assy, commonly known as CCA, is a critical component in a wide range of electronic devices. From consumer electronics to industrial machinery, CCAs are essential for ensuring the proper functioning of these devices. One company that has made a name for itself in the CCA manufacturing industry is a global leader in electronic manufacturing services. With a strong focus on innovation, quality, and customer satisfaction, the company has established itself as a trusted partner for businesses across various industries.The company's commitment to excellence is evident in its state-of-the-art manufacturing facilities and dedicated team of engineers and technicians. With a keen understanding of the latest technological advancements and market trends, the company continuously strives to develop cutting-edge CCAs that meet the evolving needs of its customers. This dedication to innovation has enabled the company to stay ahead of the competition and maintain its position as a leader in the electronic manufacturing industry.One of the key factors that set the company apart from its competitors is its unwavering commitment to quality. The company adheres to the highest industry standards and rigorous quality control processes to ensure that its CCAs meet the strictest performance and reliability requirements. This dedication to quality has earned the company numerous certifications and accolades, further solidifying its reputation as a trusted and reliable partner for electronic manufacturing services.In addition to quality, the company places a strong emphasis on customer satisfaction. By working closely with its clients and understanding their unique requirements, the company is able to deliver tailored solutions that address specific needs and challenges. Whether it's a custom-designed CCA for a niche market or a high-volume production run for a popular consumer electronics product, the company has the expertise and resources to deliver superior results.Furthermore, the company's commitment to sustainability and corporate responsibility sets it apart as a leader in the electronic manufacturing industry. By integrating eco-friendly practices into its operations and supply chain, the company strives to minimize its environmental impact and reduce its carbon footprint. This initiative not only benefits the planet but also aligns with the sustainability goals of its clients, making it an attractive partner for businesses looking to reduce their environmental impact.As the demand for electronic devices continues to grow, the company remains at the forefront of the industry, driving innovation and delivering high-quality CCAs to meet the needs of its diverse customer base. Whether it's a complex multi-layer CCA for a cutting-edge medical device or a simple circuit board for a consumer electronic product, the company has the expertise and capabilities to deliver top-notch solutions that exceed expectations.With a strong track record of success and a commitment to excellence, the company is poised to continue leading the electronic manufacturing industry for years to come. Its dedication to innovation, quality, customer satisfaction, and sustainability sets it apart as a trusted partner for businesses looking for superior electronic manufacturing services. As the industry evolves, the company remains steadfast in its mission to drive progress and deliver exceptional CCAs that power the electronic devices of today and tomorrow.

Understanding the Importance of Hipot Test Voltage in Electrical Safety Assurance

Hipot Test Voltage Technology Improves Safety in Electrical SystemsAs technology continues to advance, the demand for safer and more reliable electrical systems has become increasingly important. Companies around the world are constantly looking for innovative solutions to ensure the safety and reliability of their products. One technology that has been proven to be effective in improving electrical system safety is the Hipot Test Voltage technology.{Company Name} is a leading provider of Hipot Test Voltage technology, known for its cutting-edge solutions that help improve the safety and reliability of electrical systems. The company has been at the forefront of developing innovative testing equipment that meets the highest standards of quality and performance. Hipot Test Voltage, also known as high potential or dielectric withstanding voltage testing, is a method used to verify the insulation of electrical products or equipment. By applying high voltage to a device under test, Hipot Test Voltage technology can detect insulation issues such as punctures, cracks, and other defects that could lead to electrical hazards or malfunctions. This testing method is crucial in ensuring that electrical products are safe and reliable for use.{Company Name} has been a pioneer in the development of Hipot Test Voltage technology, continuously improving its products to meet the evolving needs of the industry. The company's range of testing equipment includes high voltage testers, insulation resistance testers, and ground bond testers, all designed to provide accurate and reliable test results.In addition to offering a wide range of testing equipment, {Company Name} also provides customized solutions to meet specific industry requirements. The company's team of experienced engineers works closely with clients to develop tailored testing solutions that address their unique needs and challenges. This personalized approach has helped {Company Name} establish itself as a trusted partner for companies looking to improve the safety and reliability of their electrical systems.One of the key advantages of Hipot Test Voltage technology is its ability to identify potential issues in electrical insulation before they cause catastrophic failures. By conducting regular Hipot Test Voltage testing, companies can proactively detect and address insulation problems, thus preventing costly downtime, repairs, or, even worse, accidents. This proactive approach to maintenance and safety has made Hipot Test Voltage technology an essential part of quality control and risk management in numerous industries.Moreover, {Company Name} has also made significant advancements in the portability and usability of its testing equipment. The company's range of lightweight and user-friendly testers allows technicians to perform tests quickly and accurately, improving efficiency and productivity. This has been especially beneficial in industries such as aerospace, automotive, and medical devices, where mobility and ease of use are critical.As the demand for safer and more reliable electrical systems continues to grow, {Company Name} remains committed to innovating and advancing Hipot Test Voltage technology. The company's dedication to quality, performance, and customer satisfaction has helped it establish a strong reputation in the industry. With a focus on continuous improvement and a customer-centric approach, {Company Name} is well-positioned to lead the way in the development of cutting-edge Hipot Test Voltage solutions.In conclusion, Hipot Test Voltage technology has proven to be a valuable tool in improving the safety and reliability of electrical systems. {Company Name} continues to be a driving force in the development of innovative testing equipment that meets the highest standards of quality and performance. With its commitment to excellence and customer satisfaction, {Company Name} is poised to remain a trusted partner for companies seeking to enhance the safety and reliability of their electrical products and equipment.

Discover the Latest Active Components for Enhanced Performance

Active Components, a leading provider of electronic components and solutions, has just announced the launch of their latest line of innovative products. The company has been a formidable presence in the industry for over a decade, known for their high-quality products and exceptional customer service.Active Components has built a strong reputation for their commitment to providing cutting-edge solutions to meet the ever-evolving needs of the electronics industry. With a team of experienced professionals and state-of-the-art manufacturing facilities, they have been able to consistently deliver reliable and high-performance components to their customers.The newly launched line of products includes a wide range of active components, such as transistors, diodes, and integrated circuits. These components are designed to meet the demanding requirements of modern electronic devices, providing superior performance and reliability. With the latest advancements in technology, Active Components has been able to develop these new products to offer enhanced functionality and improved efficiency.One of the key highlights of the new product line is the integration of advanced materials and manufacturing techniques. This has allowed Active Components to achieve higher levels of performance and durability, making their components ideal for a wide range of applications. Whether it's for consumer electronics, industrial equipment, or automotive systems, these new components are designed to meet the stringent requirements of today's most demanding applications.In addition to their commitment to product excellence, Active Components is also dedicated to providing exceptional customer support. Their team of technical experts is always on hand to assist customers with any questions or technical issues they may encounter. This level of support has helped to establish Active Components as a trusted partner for many leading companies in the electronics industry.Active Components is also known for their focus on environmental sustainability. They have implemented stringent quality control measures and green manufacturing practices to minimize their environmental footprint. By adhering to strict environmental standards, they are able to ensure that their products are not only high-performance but also eco-friendly.With the launch of their latest line of active components, Active Components is poised to further solidify their position as a leading provider of electronic solutions. Their commitment to innovation, quality, and customer satisfaction continues to set them apart from the competition.In conclusion, Active Components is a company that continues to push the boundaries of what is possible in the world of electronic components. With their latest line of products, they have once again demonstrated their dedication to providing the highest quality components for a wide range of applications. As the industry continues to evolve, Active Components remains committed to delivering innovative solutions that meet the ever-changing needs of their customers.

Cutting-Edge Technology: The Advantages of Flexible Printed Boards

Flexible Printed Board Market Expected to Grow as Demand for Flexible and Lightweight Electronics RisesThe global flexible printed board market is expected to witness significant growth in the coming years due to the increasing demand for flexible and lightweight electronic devices. Flexible printed boards, also known as FPCBs, are highly flexible and can be bent and twisted to fit into small and irregularly shaped spaces, making them ideal for use in a wide range of electronic applications.The market for flexible printed boards is being driven by the growing adoption of flexible electronics in various industries such as consumer electronics, automotive, healthcare, and aerospace. These industries are increasingly using flexible printed boards in applications such as wearables, smartphones, tablets, automotive infotainment systems, medical devices, and aircraft interiors.One company that is at the forefront of this growing market is {}. {} is a leading manufacturer of high-quality flexible printed boards that are used in a wide range of electronic applications. The company's extensive product portfolio includes single-sided, double-sided, and multi-layer flexible printed boards, as well as rigid-flex boards, which combine the benefits of both flexible and rigid printed boards.{}'s flexible printed boards are known for their high reliability, excellent thermal stability, and superior electrical performance. The company's state-of-the-art manufacturing facilities and advanced production processes ensure that its products meet the highest quality standards, making them the preferred choice for many leading companies in the electronics industry.With a strong focus on innovation and technology, {} is constantly pushing the boundaries of what is possible with flexible printed boards. The company's dedicated research and development team is continuously working on developing new materials and processes to further improve the performance and flexibility of its products. This relentless commitment to innovation has enabled {} to stay ahead of the competition and maintain its position as a market leader in the flexible printed board industry.As the demand for flexible and lightweight electronic devices continues to grow, {} is well-positioned to capitalize on this trend and further expand its market presence. The company's strong customer relationships, global distribution network, and commitment to delivering the highest quality products have earned it a reputation as a trusted and reliable partner for companies looking for flexible printed board solutions.In addition to its focus on product quality and innovation, {} is also committed to sustainability and environmental responsibility. The company has implemented stringent environmental management practices and has made significant investments in eco-friendly manufacturing processes to minimize its impact on the environment.Looking ahead, the future looks bright for the flexible printed board market, and {} is poised to play a key role in driving its growth. With its strong focus on innovation, technology, and sustainability, the company is well-equipped to meet the evolving needs of the electronics industry and continue providing cutting-edge flexible printed board solutions to its customers around the world.

How to Perform a Millivolt Test: A Step-by-Step Guide

Millivolt Test Helps Ensure Safety and Efficiency in Electronic SystemsIn today's fast-paced and interconnected world, electronic systems play a crucial role in powering everyday devices and industry operations. From consumer electronics to industrial machinery, the reliability and safety of these systems are essential for smooth functioning and preventing potential hazards. To ensure the safety and efficiency of electronic systems, millivolt testing has proven to be an indispensable tool.Millivolt testing, also known as microvolt testing, is a method used to measure the small voltage differences in electronic circuits. This testing is critical in identifying potential issues such as noise, signal interference, and voltage instability, which can lead to system malfunctions or failures. By accurately measuring millivolt levels, engineers and technicians can pinpoint problems and implement necessary adjustments to improve system performance and reliability.One company at the forefront of millivolt testing is {} (remove brand name), a leading provider of electronic testing and measurement solutions. With a rich history of innovation and expertise in the field, {} (remove brand name) has been at the forefront of developing advanced millivolt testing equipment designed to meet the ever-evolving needs of the electronics industry.Founded in (year), {} (remove brand name) has established itself as a trusted partner for companies seeking reliable and high-performance testing solutions. The company's commitment to innovation and quality has driven the development of a wide range of testing instruments, including millivolt meters, oscilloscopes, signal generators, and more. These instruments are designed to meet the rigorous demands of electronic testing across various industries, from telecommunications and automotive to aerospace and defense.One of {} (remove brand name)'s flagship products is the {} (remove brand name) Millivolt Meter, a precision instrument tailored for accurate measurement of low-level voltages in electronic circuits. The millivolt meter's high sensitivity and advanced features make it an ideal tool for identifying and troubleshooting voltage fluctuations and noise in complex electronic systems. With its user-friendly interface and reliable performance, the {} (remove brand name) Millivolt Meter has become a preferred choice for engineers and technicians worldwide.In a recent interview, (spokesperson name), a senior engineer at {} (remove brand name), emphasized the significance of millivolt testing in ensuring the safety and efficiency of electronic systems. "In today's electronic devices and circuits, even small voltage differentials can have a significant impact on overall performance and reliability. Millivolt testing allows us to uncover potential issues that may go unnoticed with conventional testing methods, thereby enabling us to deliver dependable and high-quality electronic systems," (spokesperson name) stated.The importance of millivolt testing has been further underscored by the increasing complexity of electronic systems and the growing demand for reliability and safety across industries. As technology continues to advance, the need for precise and comprehensive testing methods such as millivolt testing becomes ever more critical.With its dedication to delivering cutting-edge testing solutions, {} (remove brand name) remains committed to meeting the evolving needs of the electronics industry. By leveraging its expertise and innovative capabilities, the company continues to develop advanced millivolt testing instruments and support the development and deployment of safe and efficient electronic systems.As the reliance on electronic systems continues to grow, the role of millivolt testing in ensuring their safety and efficiency becomes increasingly vital. With the expertise and advanced solutions offered by companies like {} (remove brand name), the electronics industry can continue to drive innovation and deliver reliable and high-performance electronic systems for diverse applications.

High-Quality PCB Assembly Holder for Efficient Electronic Production

Pcb Assembly Holder is a leading provider of innovative solutions for printed circuit board (PCB) assembly and manufacturing. With a strong commitment to quality and customer satisfaction, Pcb Assembly Holder has established itself as a trusted partner for businesses in the electronics industry.The company offers a wide range of products and services to support the PCB assembly process, including high-quality assembly holders that provide secure and reliable support for PCBs during the assembly and manufacturing process. These holders are designed to accommodate a variety of PCB sizes and configurations, and offer easy adjustments for optimal positioning and stability. This allows for efficient and accurate assembly of PCBs, helping customers to achieve improved productivity and lower manufacturing costs.In addition to their comprehensive range of assembly holders, Pcb Assembly Holder also provides custom design and manufacturing services to meet the specific needs of their customers. Their team of experienced engineers and technicians work closely with clients to develop bespoke solutions that address unique challenges and requirements. This collaborative approach ensures that customers receive tailored solutions that deliver outstanding performance and value.Pcb Assembly Holder's commitment to quality is evident in their rigorous quality control processes and industry certifications. Their products are manufactured to the highest standards, using premium materials and advanced manufacturing techniques. This focus on quality and reliability has earned Pcb Assembly Holder a strong reputation for delivering products that exceed customer expectations.Furthermore, Pcb Assembly Holder is dedicated to providing exceptional customer support and service. Their knowledgeable and responsive team is available to assist customers with product selection, technical support, and after-sales service. This commitment to customer satisfaction has helped Pcb Assembly Holder to build long-lasting relationships with their clients, many of whom rely on their products and expertise for their PCB assembly needs.As a forward-thinking company, Pcb Assembly Holder is also invested in research and development to drive continuous innovation. They are constantly exploring new technologies and methodologies to enhance their products and services, and to stay ahead of industry trends. This ensures that Pcb Assembly Holder remains at the forefront of the PCB assembly market, offering cutting-edge solutions that support the evolving needs of their customers.The success and reputation of Pcb Assembly Holder are further underscored by their extensive portfolio of satisfied customers, which includes leading companies in the electronics and manufacturing sectors. These customers value Pcb Assembly Holder for their exceptional quality, reliability, and dedication to customer satisfaction. By partnering with Pcb Assembly Holder, these businesses are able to achieve greater efficiency, consistency, and cost-effectiveness in their PCB assembly processes.With a steadfast commitment to excellence and innovation, Pcb Assembly Holder continues to be a trusted and preferred partner for customers seeking high-quality solutions for PCB assembly and manufacturing. Their comprehensive range of assembly holders, custom design capabilities, stringent quality control, and exceptional customer support make them the go-to choice for businesses looking to optimize their PCB assembly processes.In conclusion, Pcb Assembly Holder's relentless focus on quality, customer satisfaction, and innovation sets them apart as a leader in the PCB assembly industry. As they continue to expand their offerings and capabilities, they are well-positioned to meet the evolving needs of their customers and to drive continued success in the market. Businesses seeking reliable and high-performance solutions for PCB assembly can confidently turn to Pcb Assembly Holder for their expertise and unmatched level of service.

Ultimate Guide to Printed Circuit Card Design and Manufacturing

Printed Circuit Card (PCC) has been making waves in the electronics industry with its cutting-edge technology and innovative approach to manufacturing. The company, founded in 1995, has quickly established itself as a leader in the production of high-quality printed circuit boards for a wide range of applications.PCC's success can be attributed to its state-of-the-art manufacturing facilities and a team of highly skilled engineers and technicians. The company's commitment to quality and customer satisfaction has earned it a reputation for reliability and excellence in the industry.PCC specializes in the production of rigid, flex, and rigid-flex circuit boards, serving customers in industries such as aerospace, medical, telecommunications, and consumer electronics. The company's capabilities include high-density interconnect (HDI) boards, multi-layer boards, and quick-turn prototypes, allowing it to meet the diverse needs of its customers.In addition to its advanced manufacturing capabilities, PCC is also known for its dedication to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and offer its customers the latest advancements in circuit board technology.One of PCC's key strengths is its ability to provide customized solutions to meet the unique requirements of each customer. Whether it's a complex multi-layer board for a medical device or a high-frequency rigid-flex board for a telecommunications application, PCC has the expertise and resources to deliver a high-quality product that meets or exceeds expectations.Furthermore, PCC is committed to sustainability and environmental responsibility in its manufacturing processes. The company adheres to strict environmental standards and continuously seeks ways to minimize its impact on the planet while delivering top-notch products to its global customer base.With its strong focus on quality, innovation, and customer satisfaction, PCC has gained the trust and loyalty of a diverse customer base. From start-ups to established multinational corporations, PCC has been the go-to partner for companies seeking reliable and high-performance printed circuit boards.Looking ahead, PCC is poised to continue its growth and expansion in the electronics industry. With a constant eye on emerging technologies and shifting customer demands, the company is well-positioned to remain a leader in the competitive market for printed circuit boards.In conclusion, PCC's dedication to excellence, innovation, and customer satisfaction has cemented its position as a leading provider of printed circuit boards. With its advanced manufacturing capabilities, commitment to sustainability, and a focus on customization, PCC is well-equipped to meet the evolving needs of the electronics industry and serve as a trusted partner for businesses worldwide.

Enhance your debugging process with the latest Testing Library

Introducing a Revolutionary Testing Library Debugging SolutionIn the fast-paced world of software development, it is critical for companies to ensure the quality and reliability of their products. With the increasing complexity of software systems, debugging has become a daunting challenge for developers. Traditional debugging methods often prove to be time-consuming and inefficient, which can ultimately lead to delayed product releases and dissatisfied customers. However, a new solution has emerged to revolutionize the process of debugging, offering developers a powerful and efficient tool to streamline their workflow and improve the overall quality of their software.With the introduction of the Testing Library Debug, developers can now have access to a cutting-edge debugging solution that promises to significantly enhance their efficiency and productivity. This new library has been intricately developed to meet the ever-evolving needs of modern software development, offering an array of features and capabilities that are designed to simplify and expedite the debugging process.The Testing Library Debug is designed to seamlessly integrate with existing development workflows, allowing developers to effortlessly incorporate it into their processes without disrupting their established practices. Additionally, the library supports a wide range of programming languages and frameworks, ensuring that it can cater to the diverse needs of developers across different platforms.One of the most notable features of the Testing Library Debug is its ability to provide comprehensive and insightful debugging information. The library utilizes advanced algorithms and techniques to capture detailed data about the software's behavior during runtime, allowing developers to gain valuable insights into the root causes of bugs and issues. This level of visibility and transparency is invaluable for developers, as it enables them to pinpoint and resolve issues with precision and accuracy.Furthermore, the Testing Library Debug offers an intuitive and user-friendly interface, making it accessible to developers of all skill levels. Its streamlined workflow and intuitive design enable developers to navigate through the debugging process with ease, minimizing the learning curve and maximizing productivity. With features such as real-time debugging and interactive breakpoints, developers can efficiently analyze and troubleshoot their code, significantly reducing the time and effort required to identify and fix bugs.In addition to its powerful debugging capabilities, the Testing Library Debug also includes a comprehensive set of tools for performance monitoring and optimization. This allows developers to identify and address performance bottlenecks and inefficiencies, ensuring that their software operates at peak performance.The Testing Library Debug is developed by {}, a leading provider of innovative software development tools and solutions. With a proven track record of delivering high-quality products to the market, {} is dedicated to empowering developers with the tools and resources they need to succeed in today's competitive landscape. The Testing Library Debug is a testament to the company's commitment to excellence and innovation, offering developers a game-changing solution that can elevate their development workflow to new heights.In conclusion, the Testing Library Debug is set to revolutionize the way developers approach debugging, offering a comprehensive and powerful solution to streamline their workflow and enhance the quality of their software. With its advanced features, intuitive interface, and seamless integration capabilities, this library is poised to become an indispensable asset for developers seeking to optimize their debugging processes. As the software development landscape continues to evolve, solutions like the Testing Library Debug will play a crucial role in empowering developers to overcome challenges and deliver exceptional products to their customers.

Top Strategies for Creating Complex PCB Designs

Complex PCB Design Takes Next Step in InnovationIn an ever-evolving technological landscape, the demand for complex PCB design has never been greater. With the exponential growth of electronic devices and technology, there is an increasing need for advanced PCB design solutions that can accommodate the intricate and sophisticated requirements of modern-day applications. This is where {company name} comes in.{Company name} is a leading provider of innovative PCB design and engineering solutions that cater to a wide range of industries including telecommunications, medical devices, aerospace, automotive, and consumer electronics. With a strong focus on R&D and a commitment to pushing the boundaries of what is possible in PCB design, {company name} has earned a reputation as a trusted partner for companies looking to leverage the latest technology in their products.The company's team of experienced engineers and designers are well-versed in the complexities of modern electronics and are constantly working to develop cutting-edge solutions to meet the ever-growing demands of the industry. This commitment to innovation has led {company name} to take the next step in the evolution of PCB design with the introduction of a new and advanced complex PCB design solution that is set to revolutionize the way electronic products are developed.The new complex PCB design solution from {company name} promises to address the challenges posed by the increasing demand for smaller, more powerful, and more reliable electronic devices. With an emphasis on high-speed signal integrity, thermal management, and miniaturization, the solution is designed to provide a comprehensive and integrated approach to complex PCB design that can meet the needs of even the most demanding applications.One of the key features of the new complex PCB design solution is its ability to handle high-density interconnects, enabling the creation of densely populated PCBs that can accommodate a large number of components in a limited space. This is crucial for applications where size and weight are critical considerations, such as in wearable devices, IoT products, and automotive electronics.Additionally, the solution incorporates advanced thermal management techniques to ensure that the PCB can operate at optimal temperatures even in challenging environmental conditions. This is essential for applications where reliability is paramount, such as in medical devices and aerospace electronics.Furthermore, the solution also includes state-of-the-art signal integrity analysis tools that enable the design team to predict and mitigate potential signal integrity issues early in the design process, thus reducing the risk of costly rework and ensuring the performance and reliability of the final product.{Company name}'s new complex PCB design solution is a testament to the company's commitment to pushing the boundaries of what is possible in PCB design. By combining expertise in areas such as high-speed design, thermal management, and signal integrity with a focus on innovation and continuous improvement, {company name} is well-positioned to meet the evolving needs of the industry and continue to be a trusted partner for companies looking to stay ahead of the technological curve.As the demand for smaller, more powerful, and more reliable electronic devices continues to grow, the need for advanced PCB design solutions will only become more critical. With its new complex PCB design solution, {company name} is poised to lead the way in addressing these challenges and helping its customers bring the next generation of electronic products to market.